Polycaprolactone (PCL): Qualities, Applications, and Long term Prospects

Polycaprolactone (PCL): Qualities, Applications, and Long term Prospects

Blog Article

Polycaprolactone (PCL) is really a biodegradable polyester using a wide range of applications in biomedical engineering, packaging, and 3D printing. Known for its excellent biocompatibility, slow degradation rate, and suppleness, PCL has changed into a key material in research and industrial applications. This article explores its properties, synthesis, uses, and future potential.

1. Chemical Structure and Properties

PCL is a semi-crystalline, aliphatic polyester - Its key properties include:

- Biodegradability: PCL degrades via hydrolysis of the company's ester linkages under physiological conditions, rendering it environmentally friendly.

- Low Melting Point (~60°C): Allows for easy processing via melt extrusion, injection molding, and 3D printing.

- High Elasticity & Toughness: Suitable for flexible applications.

- Slow Degradation Rate (2–4 years): Ideal for long-term biomedical implants.

- Good Solubility: Dissolves in organic solvents like chloroform and acetone, facilitating solution-based processing.

2. Synthesis of PCL

PCL is usually synthesized through ring-opening polymerization (ROP) of ε-caprolactone using catalysts such as stannous octoate. The reaction proceeds as follows:

1. Initiation: A hydroxyl-containing compound (e.g., ethylene glycol) reacts with ε-caprolactone.

2. Propagation: The ring opens, forming long polymer chains.

3. Termination: The reaction stops if the monomer is exhausted or deactivated.

Alternative methods include enzymatic polymerization (using lipases) for greener synthesis.

3. Applications of PCL

A. Biomedical Applications

- Drug Delivery Systems: PCL’s slow degradation allows controlled drug release.

- Tissue Engineering Scaffolds: Used in bone, cartilage, and skin regeneration due to the biocompatibility.

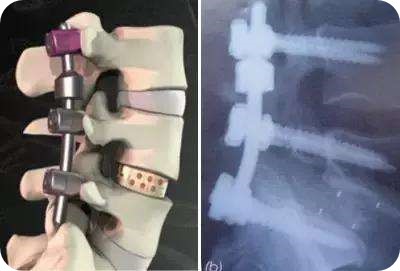

- Surgical Sutures & Implants: Absorbable PCL sutures slow up the need for removal surgeries.

B. 3D Printing & Additive Manufacturing

- Fused Deposition Modeling (FDM): PCL filaments can be used for prototyping and medical models.

- Shape-Memory Polymers: PCL-based materials can return to their original shape when heated.

C. Packaging & Environmental Uses

- Biodegradable Packaging: PCL blends with starch or PLA improve compostability.

- Agricultural Films: Degrades in soil, reducing plastic waste.

4. Advantages and Limitations

Advantages

Biocompatible and FDA-approved for medical use.

Flexible and easy to process.

Tunable degradation rate.

Limitations

Slow degradation might not suit short-term applications.

Lower mechanical strength in comparison with PLA or PET.

5. Future Prospects

Research is focused on:

- Blending PCL with polymers (e.g., PLA, PHA) to enhance properties.

- Nanocomposites incorporating hydroxyapatite or graphene for stronger scaffolds.

- 4D Printing using PCL’s shape-memory behavior for smart medical devices.

Polycaprolactone is really a versatile, biodegradable polymer with significant potential in medicine, manufacturing, and sustainable materials. As technology advances, PCL-based innovations may expand, offering greener and more efficient solutions across industries.

PCL has excellent biocompatibility, memory, biodegradability, etc. It is popular in various fields. Polycaprolactone, soft, good processability, and excellent performance, works extremely well in tissue engineering. Polycaprolactone has high crystallinity and slow degradation.